Wet finishing is the final step in making a piece of cloth on a hand loom. It is easy to think that the fabric is complete when it rolls off of the cloth storage of the loom, but that is not the case. Handwoven fabric in “loom state” is not yet finished. Wet finishing is the process of washing and drying the woven cloth for the first time.

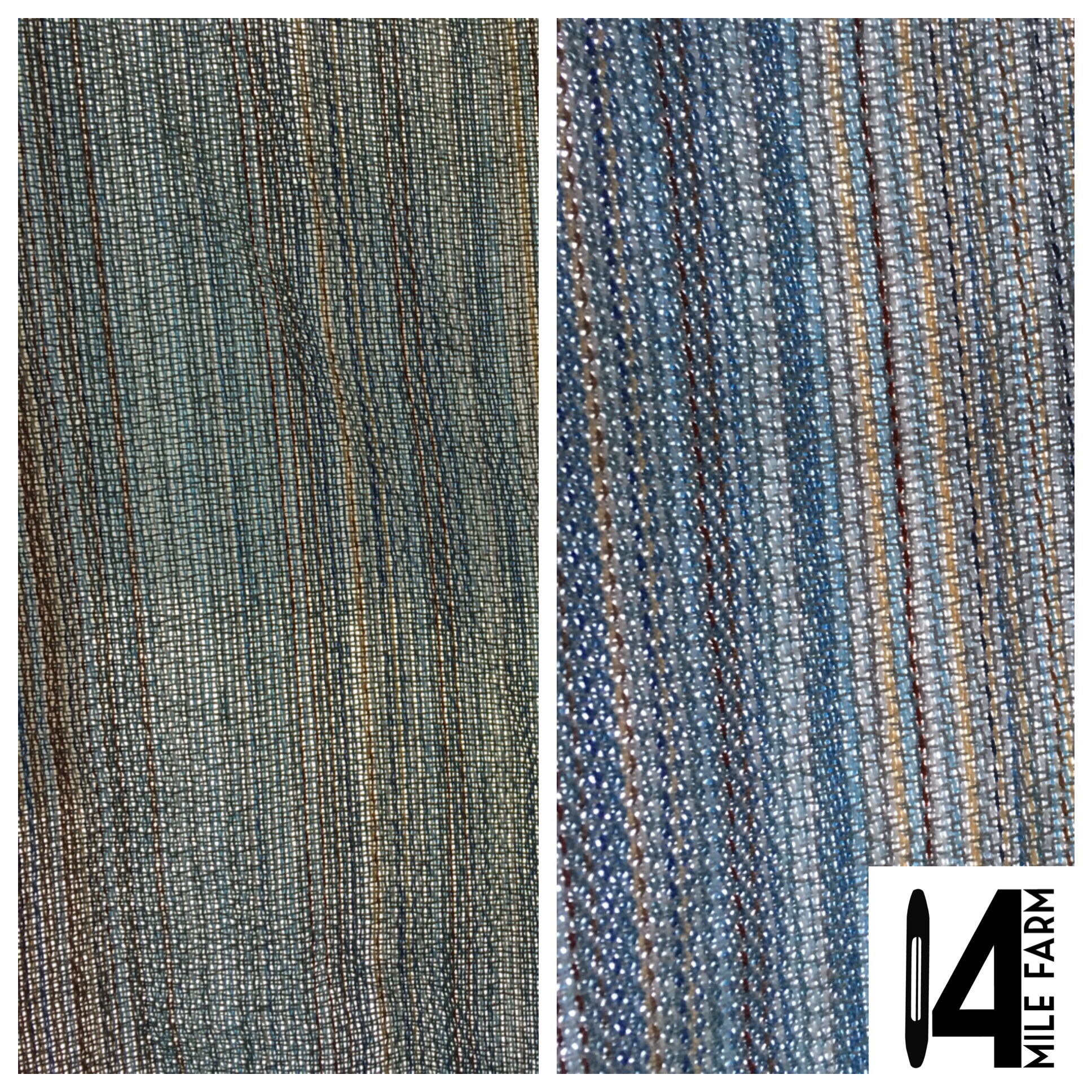

Bloom shot!

Weaving yarn is (for the most part) spun in industrial mills. The equipment that spins the yarn is lubricated with oil, and this spinning oil ends up lightly coating the spun yarn. The wet finishing process removes this oil, allowing the yarn to ‘bloom.’ As the fabric goes through the process of being washed and dried, the individual fibers in the yarn are able to fluff, shrink, and/or settle into their preferred state.

You can see the way the texture of the fabric changes, and the drape comes into being post-wet finish.

Measurements pre- and post- wet finishing can vary by 10-15% or more. Every yarn and every fiber combination will have different rates of shrinkage. In the case of wool wet finishing must be done carefully, allowing the wool to full (bloom) but not to felt. In general wool should washed in cold water with minimal agitation. Always follow your care instructions!

I was surprised by just how much the color of the warp was revealed post wet finishing. You can see the herringbone weave structure more clearly in the second photo as well. Both photos were taken in front of a window in very similar light. This change is due in part to the way that the wet finishing process lets the weft (grey here) really move three dimensionally going over and under the warp threads as it looses the two dimensionality imposed by tension on the loom.

Many machine-woven baby wraps are delivered to the customer in loom state and the buyer must do their own initial wet-finishing. Most handwoven baby wraps, and all 14 Mile Farm handwoven babywearing wraps, are delivered to the customer post wet finishing and ready to wear.